| The

Seattle Empire Laundry also displays a distinctive feature

associated with the drying process - one that is unique

to its industry.

Laundry

was still damp after being spun by the extractor. (Tumblers

for drying were just being introduced around the time

of the Empire Laundry's construction). Flatwork,

like sheets and table linens, dried while being ironed

by giant, heated rollers on the "mangle".

Clothing

was usually placed in a drying room on stationary racks,

on racks that could slide in and out of the room, or

on a movable track that wound slowly through the drying

room and automatically ejected dried items line's end. Clothing

was usually placed in a drying room on stationary racks,

on racks that could slide in and out of the room, or

on a movable track that wound slowly through the drying

room and automatically ejected dried items line's end.

These

rooms were heated by steam pipes. Good air circulation

was essential to drying clothes quickly and without

yellowing, so fans and other devices were paired with

outlets to draw moisture out of the drying rooms. Ellis

Clayton's "Manual of Modern Steam Laundry Work"

provides more detail about contemporary drying practices:

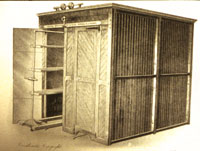

"It

is now the general practice to use propellers [on

the top of the room], so that the air is forced down

through the goods and then passes out through openings

in the apparatus just above the floor level. Drying

rooms of this kind are almost universally employed

for drying certain classes of goods at high temperatures;

they appear to have been specially introduced for

use in connection with the boiled starch process,

and, like many other machines of American design,

they are commonly built on the sectional or compartment

principle."

Clayton

later notes: "Considerable diversity of opinion

still exists respecting the best positions for the outlets

as well as the inlets of drying rooms, although many

authorities are agreed that the most efficient drying

system is one in which the heated air enters at the

top of the room and subsequently escapes through outlets

at or near the floor level. This arrangement is now

generally employed."

On

the north wall of the Empire Laundry (see photo at left),

the outlets for the drying room are clearly visible

just above the floor level of the second story. The

drying room is in near alignment with the boilers in

the basement, following standard industry practice. On

the north wall of the Empire Laundry (see photo at left),

the outlets for the drying room are clearly visible

just above the floor level of the second story. The

drying room is in near alignment with the boilers in

the basement, following standard industry practice.

As

one historian observed, "In multi-story laundries,

the drying room was often situated directly above the

boiler room in the belief that heat would be lost in

pipes that had to bend around corners." On the

interior, sections of the drying room are still extant.

As

I mentioned earlier, industrial buildings are subtle,

but they often have unique features that reveal their

original purpose. When we look at the facade

of its north wall, this is clearly the case with the

Seattle Empire Laundry.

|